Standard Gas Spring

Smooth Start, Controlled Power | Standard Gas Spring

Standard gas spring solutions by Samtek are engineered to deliver smooth, reliable, and safe motion control for a wide range of industrial, furniture, and automotive applications. Designed with advanced engineering principles and strict quality control, Samtek products ensure consistent performance and durability.

Each standard gas spring is manufactured using pressurized nitrogen gas, premium materials, and precision production processes to achieve maximum stability, vibration-free operation, and long service life. These gas springs are ideal for doors, lids, covers, and moving components that require controlled lifting and closing.Choosing the right standard gas spring improves safety, comfort, and functionality in many mechanical systems, making Samtek a trusted solution for automotive, furniture, medical, and industrial applications.

Structure and Operating Principle of Gas Springs

Gas springs utilize compressed nitrogen gas combined with hydraulic oil to regulate motion. A piston and rod assembly moves inside a sealed metal cylinder, where the pressurized nitrogen generates a constant force, ensuring controlled and stable extension.

Key performance features of these gas springs include

✅ Smooth and Vibration-Free Operation:

Thanks to the use of pressurized gas, gas springs provide smooth, stable, and consistent movement.

✅ Controlled Speed and Force:

The gas pressure can be adjusted to regulate the opening and closing speed as well as the applied force.

✅ Maintenance-Free Operation:

Unlike mechanical springs, gas springs feature a sealed system with internal lubrication, eliminating the need for periodic maintenance.

✅ High Durability and Long Service Life:

With a robust and engineered structure, gas springs offer long-lasting performance and reliable operation under various environmental conditions.

as Springs: Technical Specifications, Dimensions, and Load Capacity

One of the key advantages of Samtek Gas Springs is their full customization capability to meet a wide range of industrial requirements. Leveraging advanced engineering expertise and manufacturing experience, Samtek designs and produces gas springs in various dimensions, lengths, force ratings, and operating conditions, making them suitable for both light-duty and heavy-duty applications.

✅ Cylinder Diameter: Samtek gas springs are available in 15, 18, 21, 22, and 27 mm cylinder diameters, providing optimal solutions for different industrial uses.

✅ Length & Stroke: The overall length of Samtek gas springs can be manufactured from 100 mm up to 1.7 meters, with the stroke length precisely engineered according to the application requirements.

✅ Force Range: Samtek gas springs are produced with forces ranging from 20 N for very light applications to 4000 N for heavy-duty industrial use. For example, Samtek double folding bed gas springs can deliver up to 3500 N and offer adjustable force capability.

✅ Operating Temperature: Standard operating temperature ranges from -10°C to +120°C, while customized solutions are available for extreme conditions down to -50°C and higher temperatures upon request.

These features make Samtek Gas Springs a reliable, flexible, and professional solution across a wide range of industrial applications.

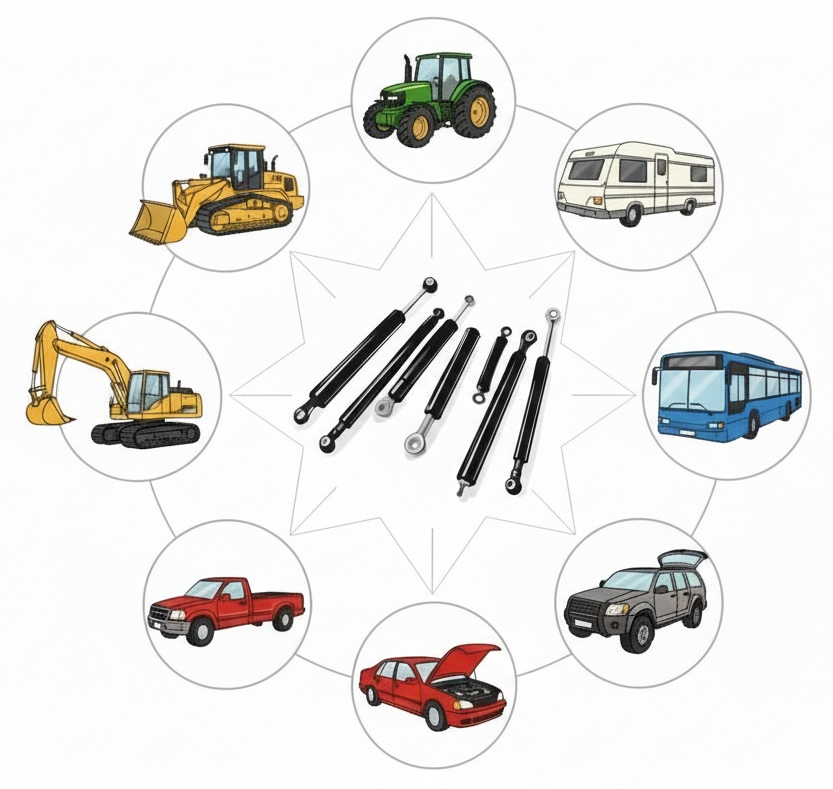

AAplications of Samtek Gas Springs in Automotive, Agricultural & Industrial Machinery

Designed for continuous operation and heavy-duty environments, Samtek gas springs are used across various machinery sectors:

🔹 Automotive Industry:

In passenger and commercial vehicles, Samtek gas springs are commonly used for hoods, tailgates, trunk lids, and service covers, providing controlled opening, improved safety, and user convenience.

🔹 Agricultural Machinery:

In tractors and agricultural equipment, gas springs assist with engine covers, access panels, and protective shields, enhancing operator safety and equipment reliability.

🔹 Construction & Industrial Machinery:

In loaders, excavators, and heavy construction equipment, Samtek gas springs help reduce mechanical stress, improve accessibility, and simplify maintenance operations.

Applications of Samtek Gas Springs in Home, Furniture & Medical Equipment

Samtek gas springs are widely used in applications where comfort, precision, and user safety are essential. These uses can be classified as follows:

🔹 Furniture & Interior Systems:

In modern furniture such as folding beds, adjustable sofas, office chairs, and storage mechanisms, Samtek gas springs enable smooth, silent, and controlled movement, significantly improving user experience.

🔹 Medical & Healthcare Equipment:

In hospital beds, stretchers, and medical devices, precise motion control is critical. Samtek gas springs provide adjustable force and stable positioning, ensuring patient safety and ease of operation for medical staff.

🔹 Household Appliances:

Applications such as kitchen hoods, lift-up panels, and movable covers benefit from Samtek gas springs by offering effortless operation and extended product lifespan.

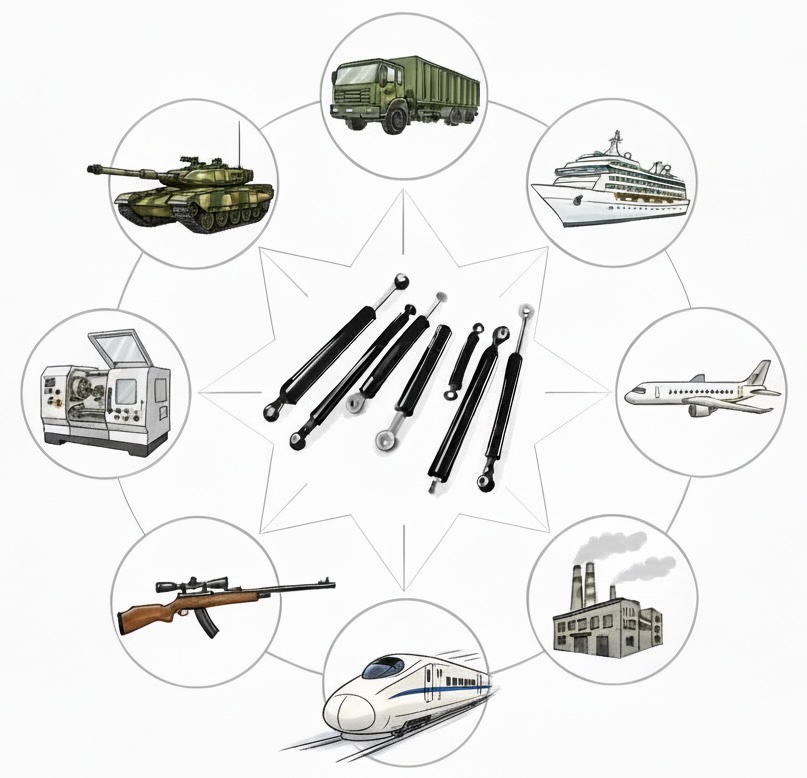

Applications of Samtek Gas Springs in Military, Transportation & Heavy Industries

Samtek Gas Springs are widely used in military, transportation, and heavy-duty industrial applications, where reliability, safety, and controlled motion are critical. These applications are categorized as follows:

🔹 Military & Defense Equipment:

In military vehicles, armored systems, and defense equipment, Samtek gas springs are used for access covers, hatches, protective enclosures, and movable components. Their smooth and controlled motion enhances operator safety and ensures reliable performance under extreme conditions.

🔹 Aerospace, Rail & Marine Transportation:

In aircraft, trains, and marine vessels, gas springs are applied in service panels, inspection covers, storage compartments, and access doors. Samtek gas springs provide stable and vibration-resistant operation in demanding environments.

🔹 Heavy Industrial Facilities:

In factories and heavy industrial machinery, Samtek gas springs improve maintenance accessibility, operational safety, and long-term durability, making them an essential component of modern industrial systems.

Warranty, After-Sales Service & Custom Gas Spring Solutions

📢 We are not just a gas spring supplier — we are your long-term partner in product development and optimization.At Samtek, we stand behind the quality of our gas springs and support our customers at every stage, from design to long-term operation.

🔹 14-Month Official Warranty:

All Samtek gas springs are covered by a 14-month official warranty, reflecting our confidence in product quality, durability, and consistent performance.

🔹 Full Customization Options:

We offer complete customization, including force rating, overall length, stroke, end fittings, and technical specifications, tailored precisely to your application requirements.

🔹 Comprehensive After-Sales Support:

Our experienced technical support team provides professional consultation, application guidance, and after-sales services, helping you select and maintain the optimal gas spring solution.

🔹 Special Gas Spring Design Capabilities:

For demanding environments such as high or low temperatures, chemical exposure, heavy impacts, or harsh operating conditions, Samtek designs and manufactures special-purpose gas springs with customized performance characteristics.

📞 Contact our experts today and receive a gas spring solution perfectly matched to your application needs.